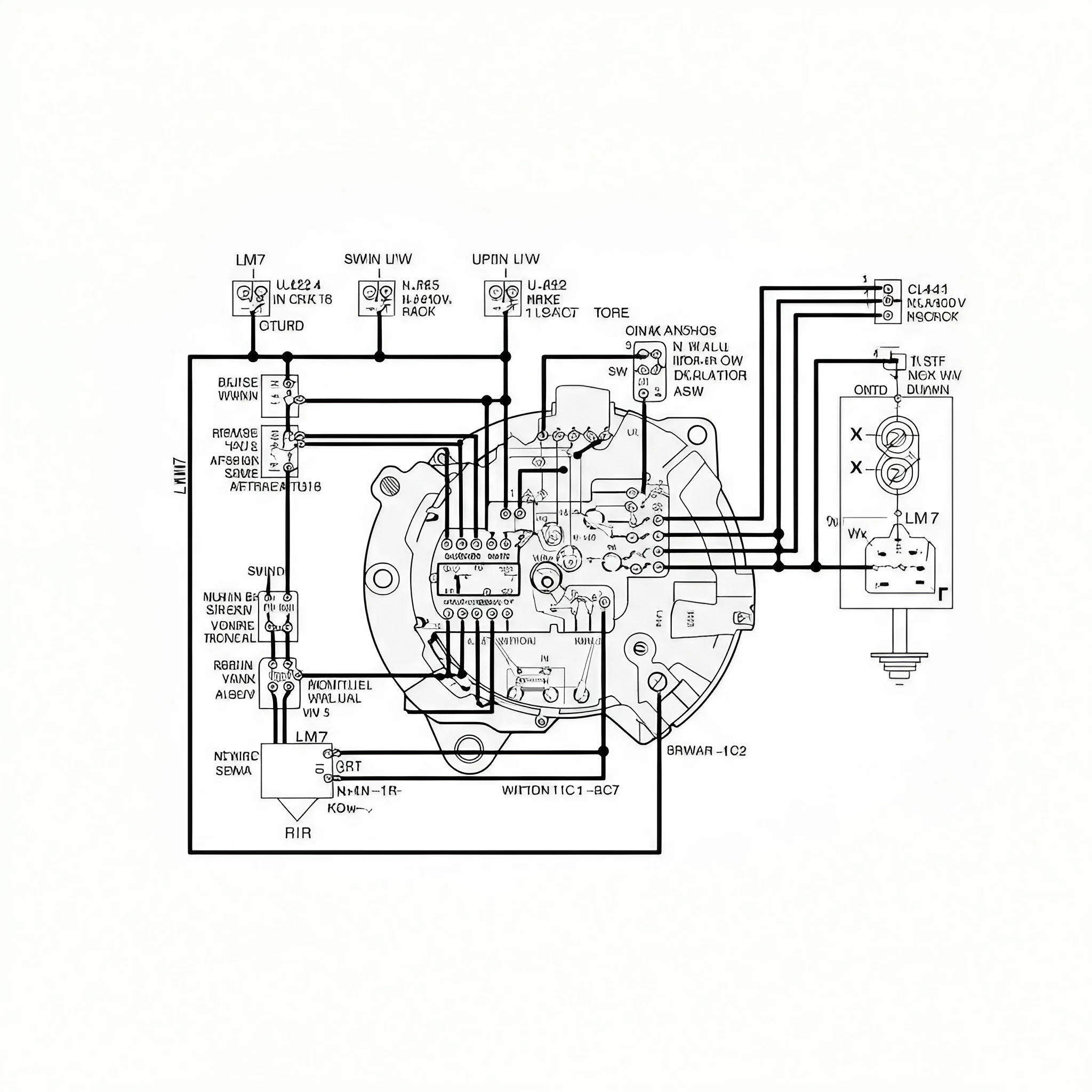

When it comes to alternator wiring, one of the most searched setups is the LM7 4 pin to 1 cable alternator wiring diagram. This guide walks you through every detail you need to master this essential alternator wiring process. Whether you’re building a project car, upgrading your vehicle’s electrical system, or simply troubleshooting your alternator wiring, this post will help you understand how to wire your LM7 alternator properly and efficiently.

By the end of this post, you’ll not only understand the wiring diagram but also how to ensure a proper connection that powers your vehicle’s electrical system reliably.

What Is an LM7 Alternator?

The LM7 alternator is typically associated with GM’s 5.3L Vortec engine found in various vehicles from the early 2000s. This alternator is known for its efficiency and durability. What makes the LM7 alternator wiring unique is the way it converts a factory 4-pin connector into a simplified 1-wire setup—a popular choice for those tackling engine swaps or simplifying their engine bay.

Rather than utilizing the original 4-wire plug, the 1-wire method simplifies the process while maintaining effective charging.

Why Convert to a 1-Wire Alternator Setup?

Here are some of the benefits of converting from a 4-pin alternator to a 1-wire wiring system:

- Simplified Installation: A 1-wire system eliminates unnecessary wires for a cleaner and more organized engine bay.

- Improved Reliability: Fewer wires mean fewer chances of wear, loose connections, or failures.

- Enhanced Adaptability: Ideal for custom builds, LS swaps, or vehicles needing an updated alternator system.

While both setups achieve the same end goal—charging your vehicle’s battery and powering electrical systems—the 1-wire configuration streamlines the process, especially for projects or custom builds.

The Wiring Basics of an LM7 Alternator

Before we dive into the specific wiring diagram, it’s helpful to understand the basics of alternator wiring.

The 4-Pin Connector

The 4-pin connector on the LM7 alternator is standard for its original setup. Here’s what each pin typically represents:

- Pin L (Lamp): Provides the signal to the dashboard warning light.

- Pin F (Field): Used for regulator control.

- Pin S (Sense): Monitors battery voltage and adjusts charge accordingly.

- Pin P (Pulse): Outputs signals for the vehicle’s tachometer.

The 1-Wire Conversion

The 1-wire alternator bypasses much of this complexity. Instead of utilizing all four pins, it focuses on a simple connection that handles the charging process. The alternator senses voltage internally, eliminating the need for additional external connections.

Next, we’ll break down the LM7 4 pin to 1 cable alternator wiring diagram for practical application.

Step-by-Step Guide: LM7 4 Pin to 1 Cable Alternator Wiring Diagram

Before starting, ensure you have the following tools and materials handy:

- Wiring harness or adapter kit (if needed)

- Multimeter to test connections

- Electrical tape or heat shrink tubing

- Wire cutters and crimpers

Step 1—Locate the Alternator and Remove the Old Connector

Begin by safely disconnecting your vehicle’s battery. Locate the 4-pin connector at the back of your LM7 alternator. Remove the plug and inspect the wiring for wear or damage.

Step 2—Identify the Primary Charging Wire

From the alternator’s original 4-pin layout, you’ll mainly work with the “L” (Lamp) wire that feeds into the warning light system. For a single-wire setup, this component is typically routed directly to the positive battery terminal or fuse box post for voltage supply.

Step 3—Install a 1-Wire Adapter (Optional)

If you have a wiring adapter kit, connect it to the alternator’s terminal. These kits simplify routing by consolidating the wires into just one cable.

Step 4—Connect the Battery Connection

The large output terminal of the alternator, typically labeled “BAT” or “B+,” connects directly to the positive terminal of the battery. Use an appropriate gauge cable for this connection to handle the current flow.

Step 5—Secure Grounding

Ensure the alternator is well-grounded to the engine or chassis. The ground connection is critical for the alternator to function correctly.

Step 6—Test the System

Reconnect your vehicle’s battery. Use a multimeter to confirm proper voltage output when the engine is running. A healthy alternator should produce around 13.8 to 14.4 volts at idle.

Optional—Install a Warning Light

For those who prefer a dashboard warning light, connect the “L” wire from the original 4-pin connector to the light. This step is optional for many 1-wire setups, as the alternator regulates itself internally.

Troubleshooting Common Issues

While the process may seem straightforward, issues can occur. Here’s how to handle common wiring problems:

- Low Voltage Output: Check your connections, especially the main battery wire, and ensure the alternator is charging within the recommended range.

- Dashboard Warning Light Always On: This indicates a potential short or incorrect connection to the warning light wire. Verify the wiring path for continuity.

- Overcharging: If the alternator outputs more than 14.5 volts, the internal regulator may be faulty or damaged.

Frequently Asked Questions

Can I use a stock alternator for a 1-wire setup?

Yes, you’ll need an internal regulator or adapter to make your stock LM7 alternator compatible with a 1-wire configuration.

Is a 1-wire alternator better for engine swaps?

Absolutely. The simplicity of the 1-wire setup makes it perfect for custom builds or LS swaps, where reducing clutter and simplifying wiring is a priority.

Do I need an external voltage regulator with a 1-wire alternator?

No. Most 1-wire alternators include an internal voltage regulator, making external regulators unnecessary.

Power Your Electrical System the Right Way

By following this step-by-step guide to wiring an LM7 4-pin to 1-cable alternator, you can simplify your setup, improve reliability, and keep your vehicle performing at its best. Whether you’re a seasoned mechanic or a DIY enthusiast, understanding your alternator wiring is a key skill that can save you time and effort in the long run.